In the ever-evolving landscape of thermal management, micro channel heat exchangers have emerged as innovative solutions that are reshaping the way heat transfer is handled across various industries. With their compact design, high efficiency, and versatility, micro channel heat exchangers are revolutionizing thermal management practices and opening up new possibilities for optimizing heat exchange processes.

Compact Design, Powerful Performance

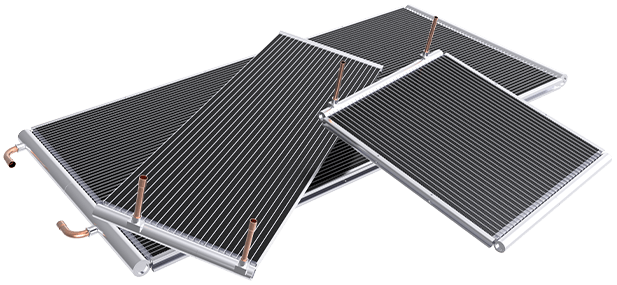

One of the defining features of micro channel heat exchanger is their compact design, which maximizes the surface area available for heat transfer while minimizing space requirements. Unlike traditional heat exchangers, which rely on larger channels and bulkier designs, micro channel heat exchangers leverage a network of small channels with diameters typically less than a millimeter. This compactness not only allows for efficient heat transfer in confined spaces but also enables more precise temperature control and faster response times.

Enhanced Efficiency and Energy Savings

Micro channel heat exchanger offer exceptional thermal performance, thanks to their high surface area-to-volume ratio and optimized fluid flow pathways. By maximizing heat transfer rates, these innovative devices enable more efficient cooling and heating processes, leading to significant energy savings and reduced operating costs. Whether used in electronics cooling, HVAC systems, or industrial processes, micro channel heat exchangers help organizations minimize energy consumption while maintaining optimal thermal conditions.

Versatility Across Industries

The versatility of micro channel heat exchangers extends across a wide range of industries and applications. In the electronics sector, micro channel heat exchangers play a crucial role in cooling high-power electronic components, ensuring reliable performance and extending device lifespans. In automotive applications, these heat exchangers contribute to improved engine efficiency and reduced emissions by efficiently dissipating heat from engine components and hybrid electric vehicle batteries.

Sustainability and Environmental Impact

In addition to their efficiency and versatility, micro channel heat exchangers offer sustainability benefits that align with environmental conservation efforts. By reducing energy consumption and greenhouse gas emissions, these devices help mitigate the environmental impact of thermal management processes. Furthermore, their compact design and lightweight construction result in lower material usage and reduced waste, contributing to overall resource conservation and sustainability.

Advancements in Materials and Manufacturing

Continual advancements in materials science and manufacturing techniques are driving further innovation in micro channel heat exchanger technology. Engineers are exploring new materials with enhanced thermal conductivity and corrosion resistance properties, as well as novel manufacturing processes such as additive manufacturing and micro-machining. These advancements enable the production of micro channel heat exchangers with improved performance, durability, and cost-effectiveness, further expanding their applicability across industries.

Future Outlook

As technology continues to evolve and industries strive for greater efficiency and sustainability, the role of micro channel heat exchangers in thermal management will only grow in importance. Ongoing research and development efforts are focused on enhancing the performance, reliability, and scalability of micro channel heat exchanger systems. With their ability to deliver powerful thermal management solutions in compact, energy-efficient packages, micro channel heat exchangers are poised to remain at the forefront of innovation in the field of thermal engineering for years to come.